Has any one ever tried making their own 90 degree 24pin adapter?

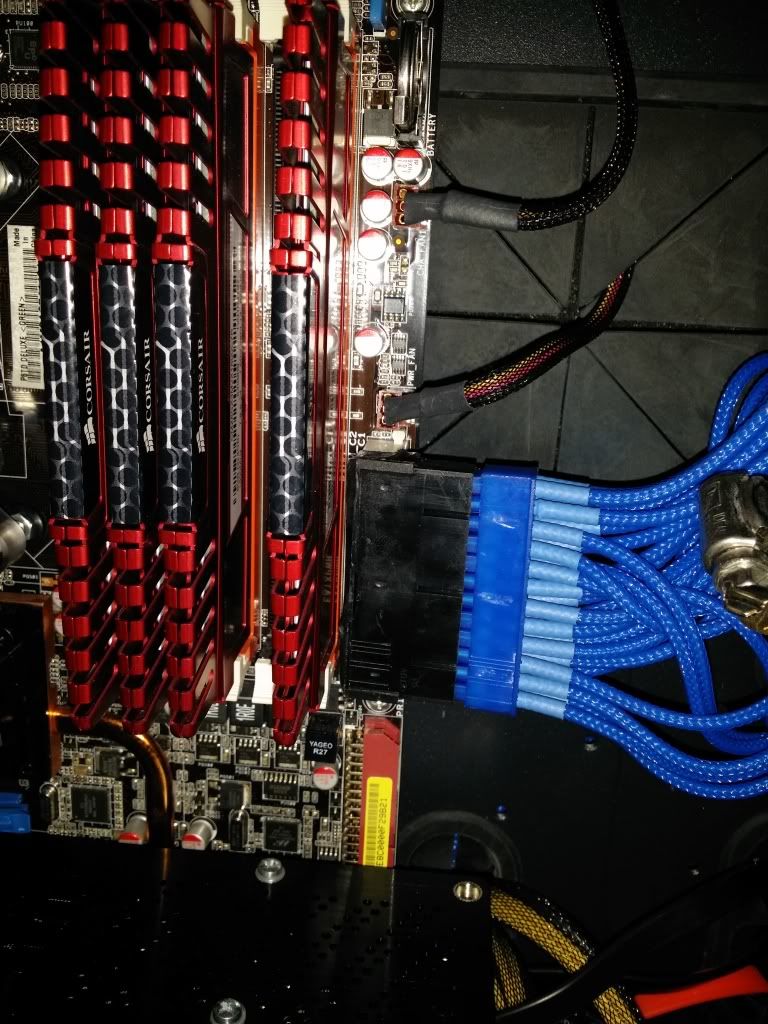

I don't mean these ones you can buy at different stores.

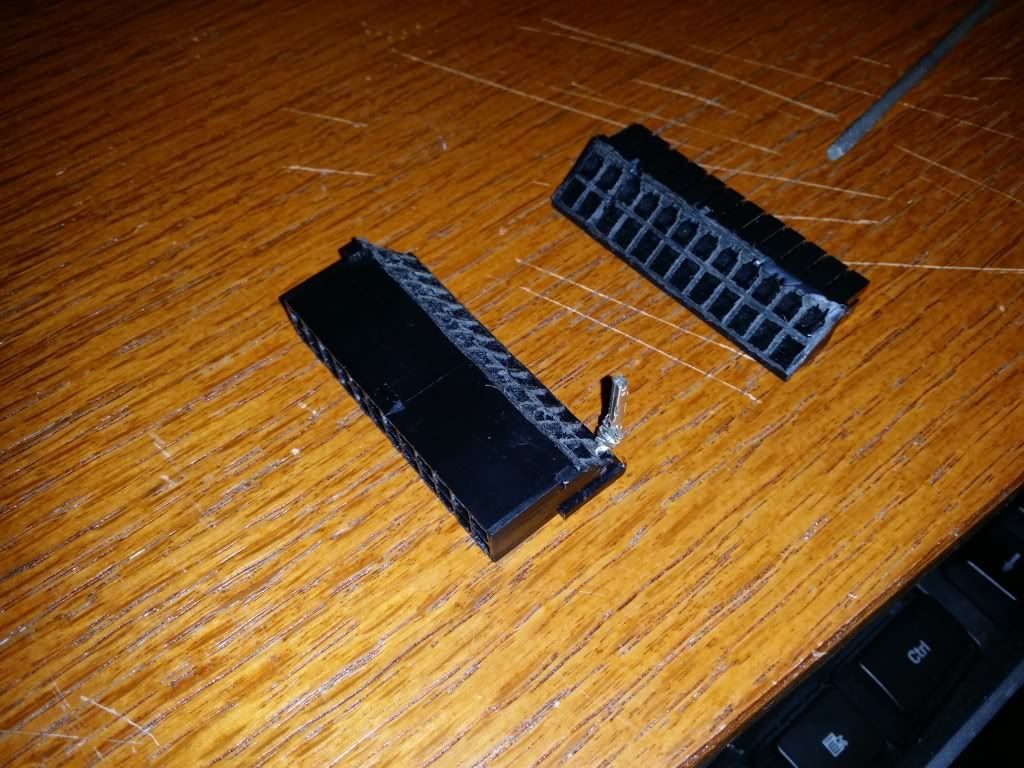

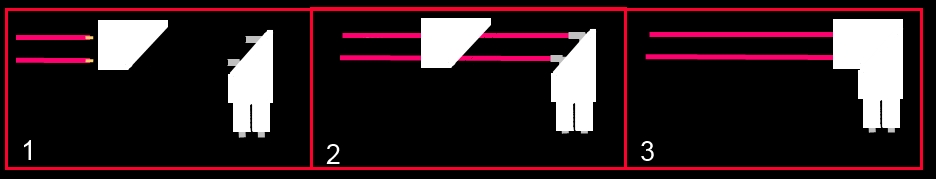

I'm talking about taking a 24 pin extension, using just the heads and somehow connect them.

So it could be used on any board, without soldering (will require soldering while making it, though).

I am planning on making one, and just wanted to see if anyone had some input.

I can add that I am about to finish a 90 molex connector (female to male) that turned out better than I expected. Only issue is painting it. Will post pictures soon.

I don't mean these ones you can buy at different stores.

I'm talking about taking a 24 pin extension, using just the heads and somehow connect them.

So it could be used on any board, without soldering (will require soldering while making it, though).

I am planning on making one, and just wanted to see if anyone had some input.

I can add that I am about to finish a 90 molex connector (female to male) that turned out better than I expected. Only issue is painting it. Will post pictures soon.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)